FLUORESCENT MARKINGS

A fluorescent marking is virtually independent of patterns, colors, or surface properties, and can be used on almost any carrier material. The fluorescent colorant is able to return a visible spectrum when excited with short-wave light (approx. 370-380nm).- Tasks in manufacturing processes (guiding, monitoring, sorting)

- Packaging machines (e.g. control during cutting, folding)

- Ceramics industry (e.g. positioning of parts)

- Wood industry (e.g. cutting/wood markings)

- Textile industry (e.g. cutting guides)

- Food industry (e.g. identification)

- And others. Ask us!

APPLICATION EXAMPLES FLUORESCENT MARKINGS

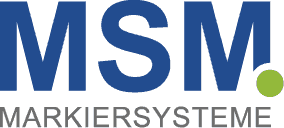

LINE MARKINGS ON WOOD AT HIGH PROCESS SPEEDS

Fluorescent markings on wood as error/wood markings in optimizing cross cut saws. Marking width 60mm. Marking time min. 2ms. Detectable with the high-performance luminescence scanners of the LMT4 sensor series, even when there are: resin pockets, different wood qualities and types, untreated construction timber up to coated or painted wood for furniture, floors, or other finished goods from the wood processing industry.

MSM also offers a broad range of additional marking options for a wide variety of different projects. Our marking systems are extremely versatile: from high-speed applications for fast production lines to fluorescence marking systems or even flexible high-quality markings up to marking systems with thermal properties – the selection of reliable marking possibilities is huge.

DOT MARKINGS ON PLUGS AT HIGH PROCESS SPEEDS

Fluorescence marking on metal for FIFO markings in manufacturing processes. Marking size 4mm. Marking time min. 2ms. Detectable with the high-performance luminescence scanners of the LMT4 sensor series, even on dark, structured surfaces.

MSM also offers a broad range of additional marking options for a wide variety of different projects. Our marking systems are extremely versatile: from high-speed applications for fast production lines to fluorescence marking systems or even flexible high-quality markings up to marking systems with thermal properties – the selection of reliable marking possibilities is huge.

Stainless steel markings

Rolled stainless steel with detectable fluorescent UV markings for the automation of inspection processes.

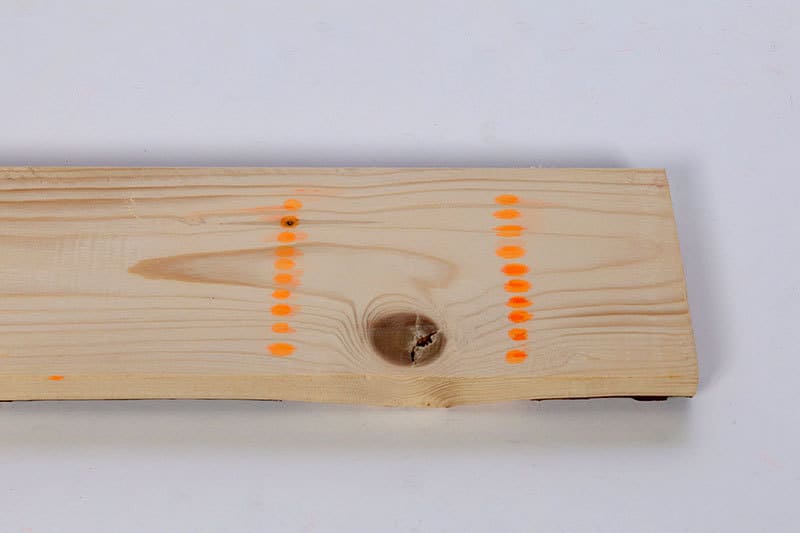

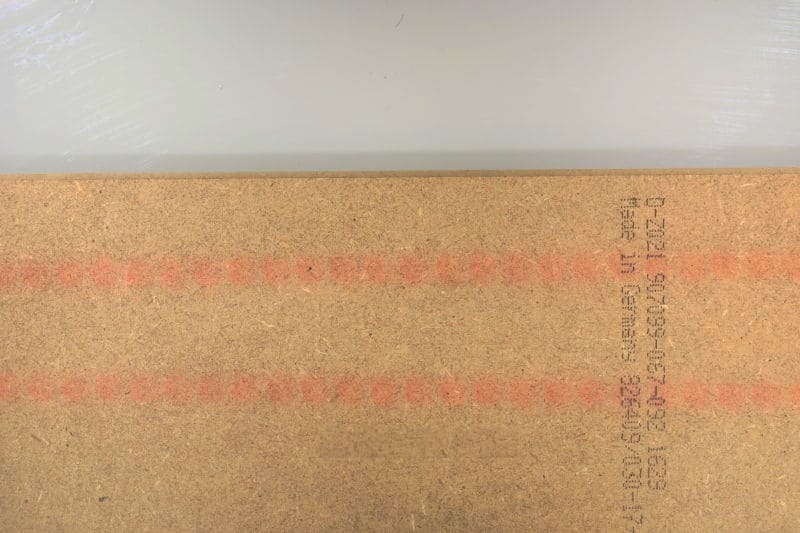

Wood markings

MDF panels with a visible or invisible colorless UV marking. Whether planed goods, laminated wood beams, sawn timber, multilayer boards, laminates and much more: Any surface can be marked reliably with a fluorescent mark.

Fluorescent markings from left image in UV light. The clearly detectable fluorescent marking can be used to check quality or types, cutting markings and more in wood processing and the furniture industry.