WEB MARKINGS

Length units, typing, product properties, and much more can be marked using dot or line codes and can then be analyzed using a camera system or other optical sensors.For this, marking devices and sensors will be used in the manufacturing process and in the later downstream production of the web product. Generally in the area of paper, metal, or plastics. Nowadays, code and error markings are used in the processing industry for quality assurance and process optimization purposes. MSM's marking devices offer the possibility of edge markings and/or web markings.

- Tasks in manufacturing processes (guiding, monitoring, sorting)

- Plastics industry (e.g. calibration)

- Paper industry (e.g. error marking)

- Printing industry (e.g. error marking)

- Metal industry (e.g. coil marking)

- And others. Ask us!

APPLICATION EXAMPLE WEB MARKING

AUTOMATICALLY READABLE CODING AND WEB MARKINGS

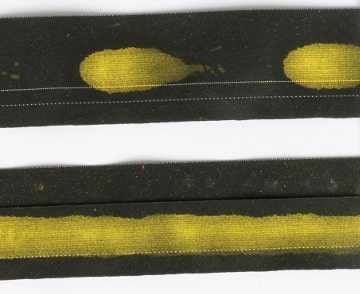

EDGE MARKING WEB MARKING ON PAPER/FILM

Length coding calibration

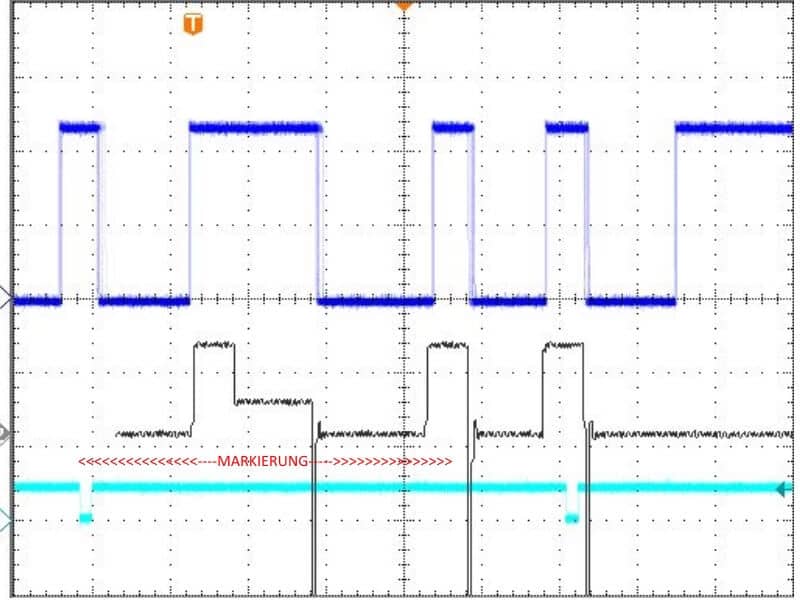

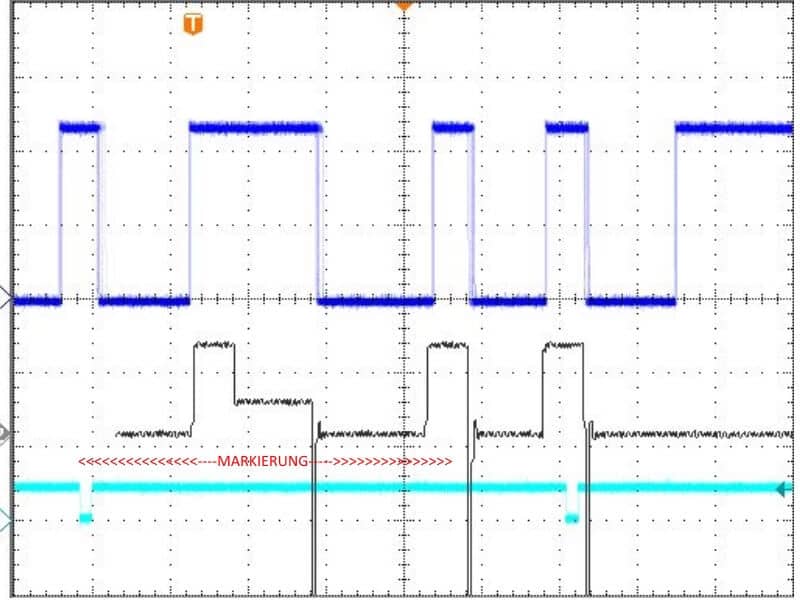

Calibration and error marking is carried out by a marking system / marking device. The length units are specified by a binary coding which is detected by a camera system as it is wound up to either reject the units or transfer them to downstream manufacturing processes.

For example, there are numerous material errors that can occur in a production line using a calendar. The length positions of the produced materials and the detected errors are entered into a database. In manufacturing, the system then moves to the exact error position to cut out the defective material. The material position is also registered with the encoder here as well. In the process, cutting scrap, slack, and material stretching lead to differences between the original length measurement and the measurement at the winder, making it impossible for the system to approach the exact error position. To synchronize the two length measurements, a length coding (edge coding) can be applied to the material during production.

Error marking scrap marking

Especially for film, paper, print products, and other web products, their later usability can only be controlled using complex camera systems (image recognition) and sensors (ultrasound, metal detector, scanner). The quality standards for these products are often particularly high. But there are many factors that can interfere with the quality of the product: Material that did not melt completely, foreign objects or wear and tear inside the machine, insects or everyday defects such as scratches, air pockets, thin areas, or burns can reduce the value of the produced web products up to the downstream production processes.

The MSM marking device / marking system reliably marks scrap after the inspection, even at changing web speeds.

Benefits of web marking edge marking:

- Non-contact marking

- Very gentle on materials

- Can be used at virtually unlimited, changing web speeds

- Highly visible and invisible markings possible

- Reliable marking

- Without adhesion errors as can occur with flags or labels

Edge marking paper

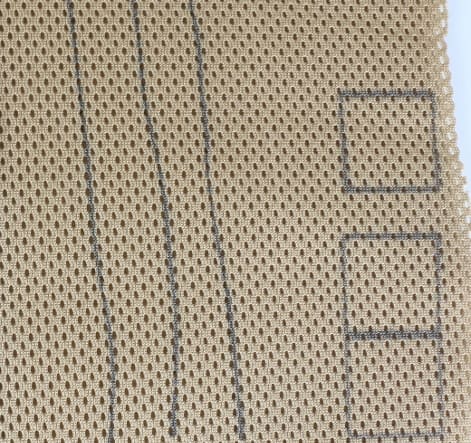

Increase your productivity by optimizing your textile machines and making them fail-proof. Intelligently controlled production will make your work easier and provide you with a high potential, especially for the processing of large quantities. Example of a cutting marking for cut-outs on fabrics and colored nonwovens with different structures. Controlled using a plotter system and a CO2 laser machine.