ERROR MARKINGS

In automated production, marking technology and especially the error marking of work pieces are used for subsequent rejection processes. This makes it possible to rework the features and reduce scrap.- Tasks in manufacturing processes (monitoring, sorting)

- Automotive industry (e.g. after inspection tasks)

- Plastics industry (e.g. quality control)

- Metal industry (e.g. imperfections)

- Wood and paper industry (e.g. imperfections)

- And others. Ask us!

APPLICATION EXAMPLES ERROR MARKINGS

INSPECTION MARKING hardened saw blade – STEEL MARKING

Marking of a saw blade for band sawing after a camera inspection for visual / automatic quality assessment during the unwinding of the coil. Accurate application of marking dots and line markings. Marking monitoring of the mark applicator possible. Excellent recognition even in limited spaces and for different geometries.- Marking color red (all primary colors can be supplied)

- Short drying times

- Excellent visibility

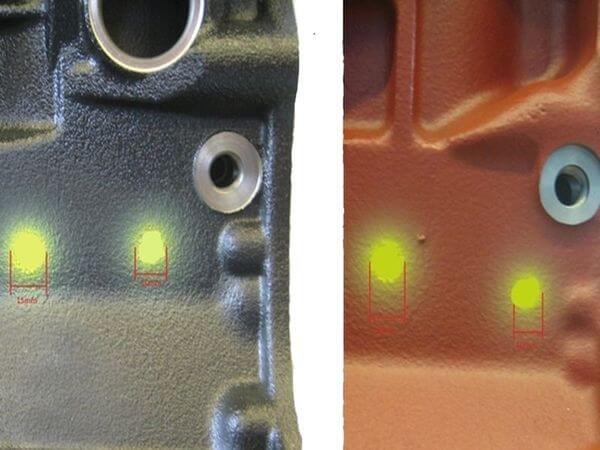

ERROR MARKING ON PAINTED ENGINE BLOCKS

Fluorescent markings for the visual and automatic recognition of defective units on engine blocks. Highly visible / invisible markings on oily, structured surfaces possible.

- Marking color yellow (all primary colors can be supplied)

- Short drying times

- High visibility

STEEL TUBE MARKING AFTER INSPECTION OF THE INDUCTION WELDING

INSPECTION MARKING STEEL TUBE – STEEL TUBE MARKING

Marking of a steel tube after induction welding for visual / automatic quality assessment. Accurate application of marking dots and line markings. Marking monitoring of the mark applicator possible. Excellent recognition even on rough and dark surfaces.

- Marking color green (all primary colors can be supplied)

- Very short drying times

- Good abrasion resistance

INSPECTION MARKING ON NONWOVEN FABRIC NONWOVEN MATERIAL

ERROR MARKING NONWOVEN FABRIC NONWOVEN MATERIAL

Error marking of highly complex 3-dimensional fabric in running production by applying fast-drying marking fluid. Wide variety of application possibilities for different yarns and weaving techniques thanks to special marking fluids.

- Marking fluid yellow (all primary colors can be supplied)

- Short drying times

- Marking only possible on the surface

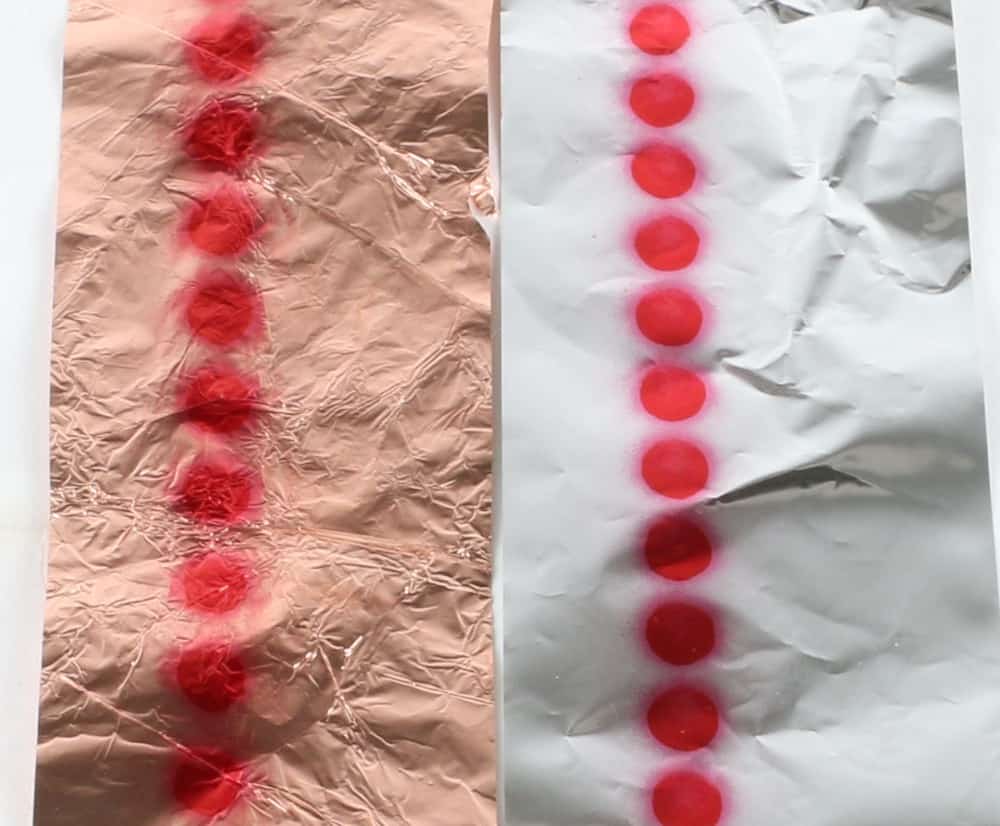

ERROR MARKING ON COPPER FOIL AND ALUMIMUM FOIL

INSPECTION MARKING AFTER VISUAL CAMERA INSPECTION

Marking after visual inspection / automatic quality assessment. Accurate application of marking dots and rows of dots. Marking monitoring during the application of the marks possible. Excellent recognition even on reflecting and darker surfaces.

- Marking color red (all primary colors can be supplied)

- Short drying times

- Excellent abrasion resistance

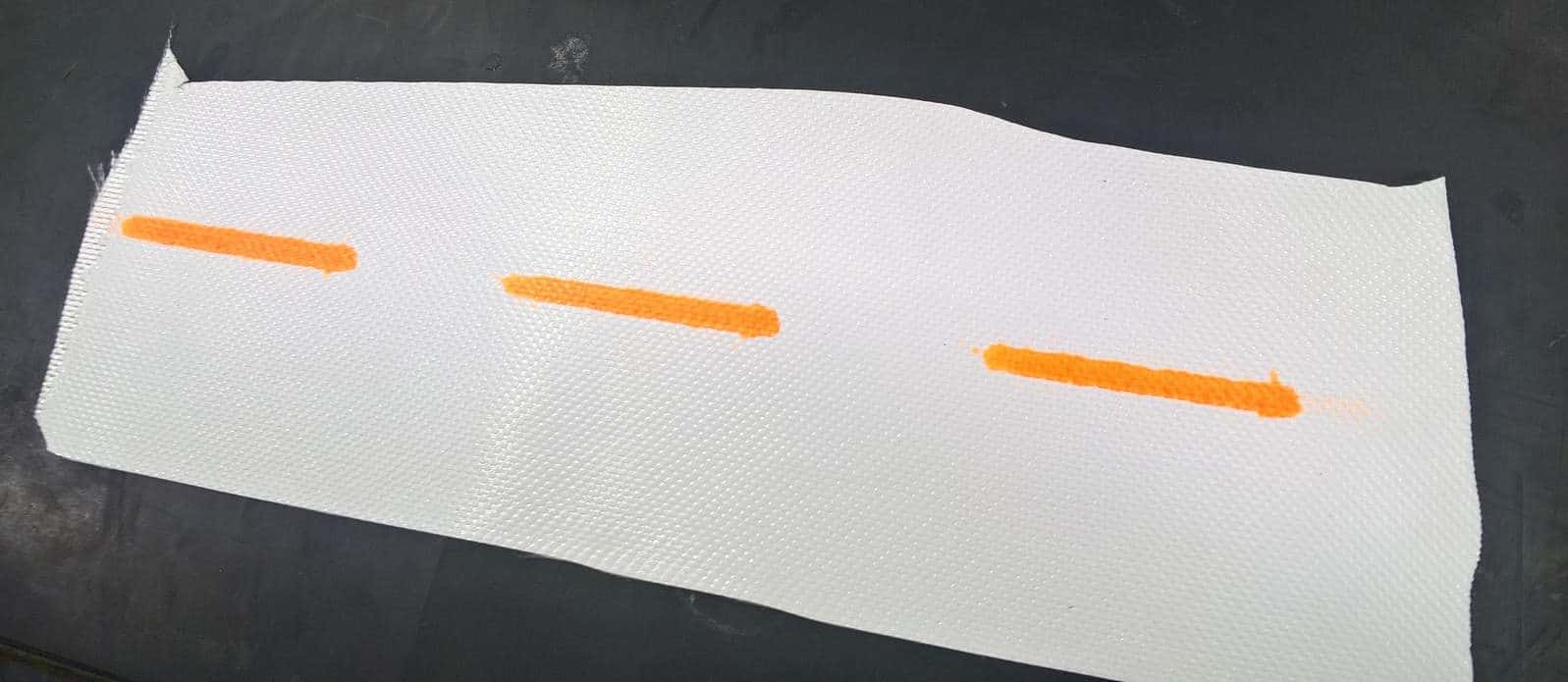

ERROR MARKING ON PVC FILM CARRIER MATERIAL

INSPECTION MARKING AFTER AUTOMATIC ERROR DETECTION

Marking after lamination error with automatic quality assessment. Accurate application of marking lines with marking monitoring during the application of the marks. Good recognition even on different color variants and darker surfaces.

- Fluorescence marking color orange (all primary colors can be supplied)

- Short drying times

- Excellent abrasion resistance