Marking technology applications

Applications of marking technology – MSM marking systems and their marking technology are designed for a wide range of industrial marking technology and automation applications. They ensure functionality and optimize downstream process in production and logistics. Whether single dots, rows of dots, or even dotted lines or line markings: The markings can be adapted on an individual basis.Marking systems and marking devices are used around the world to make production automation, quality assurance, and testing considerably easier:

- Color markings and fluorescent markings for typing or identification

- Line markings and dot markings for good/bad markings

- Fitting markings

- Position markings

- Marking devices for the most difficult of industrial conditions, with dust, dirt, and heat

- Different marking heads with variable nozzle diameters and versions

- And a lot more...

- Ask us!

A PERFECT FIT

Our testing process

Applications can be very complex. There can be a whole host of interactions between the individual parameters:

Whether for wood, plastic, metal, rubber or other materials – with our marking technology, we will provide you with proactive support for your project. With decades of experience working alongside our customers, we know the workflows, processes, and requirements in every detail. To provide you with marking systems tailored to your individual needs, we will carefully analyze your entire processes to determine your exact marking technology requirements.

Material properties and their surface structures, marking fluids, and sensors determine the efficiency and the practical implementation possibilities in marking technology.

MSM-Technik – Marking Technology – DOD Inkjet Systems

Your partner and system supplier for customized markings.

Whether for wood, plastic, metal, rubber or other materials – with our marking technology, we will provide you with proactive support for your project. With decades of experience working alongside our customers, we know the workflows, processes, and requirements in every detail. To provide you with marking systems tailored to your individual needs, we will carefully analyze your entire processes to determine your exact marking technology requirements.

Material properties and their surface structures, marking fluids, and sensors determine the efficiency and the practical implementation possibilities in marking technology.

MSM-Technik – Marking Technology – DOD Inkjet Systems

Your partner and system supplier for customized markings.

We offer you:

All components in industrial marking technology are developed and manufactured in top quality on an individual basis to meet customer requirements. MSM's marking technology has proven itself over many years, ensuring reliable processes and consistently high quality in product markings.

We offer marking systems as complete concepts. Development, production, and service is done in-house to offer you flexibility and reliability for each of your projects.

- Expertise and years of experience

- Reliability and flexibility

- Optimum application advice

- Professional service

- Worldwide spare parts supply

All components in industrial marking technology are developed and manufactured in top quality on an individual basis to meet customer requirements. MSM's marking technology has proven itself over many years, ensuring reliable processes and consistently high quality in product markings.

We offer marking systems as complete concepts. Development, production, and service is done in-house to offer you flexibility and reliability for each of your projects.

FLUORESCENT MARKINGS

A fluorescent marking is virtually independent of patterns, colors, or surface properties, and can be used on almost any carrier material. The fluorescent colorant is able to return a visible spectrum when excited with short-wave light (approx. 370-380nm).

A fluorescent marking is virtually independent of patterns, colors, or surface properties, and can be used on almost any carrier material. The fluorescent colorant is able to return a visible spectrum when excited with short-wave light (approx. 370-380nm).ERROR MARKINGS

In automated production, marking technology and especially the error marking of work piece are used for downstream rejection processes. This makes it possible to rework features and reduce scrap.

In automated production, marking technology and especially the error marking of work piece are used for downstream rejection processes. This makes it possible to rework features and reduce scrap.INSPECTION MARKINGS

Inspection markings ensure quality and identify the different product properties in relation to specified parameters.

Inspection markings ensure quality and identify the different product properties in relation to specified parameters.FITTING MARKINGS

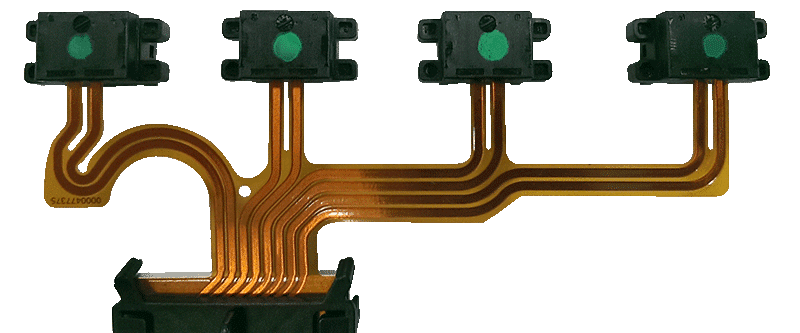

Position markings, fitting marks, line markings, or rows of dots reliably ensure fixed points in manufacturing processes. In modern industrial manufacturing and inspection, more and more processes are automated. Here, position markings are an important part of process reliability and processing results.

Position markings, fitting marks, line markings, or rows of dots reliably ensure fixed points in manufacturing processes. In modern industrial manufacturing and inspection, more and more processes are automated. Here, position markings are an important part of process reliability and processing results.

QUALITY MARKINGS

Quality markings ensure a reliable and consistent flow of materials in manufacturing processes.

Quality markings ensure a reliable and consistent flow of materials in manufacturing processes.WEB MARKINGS

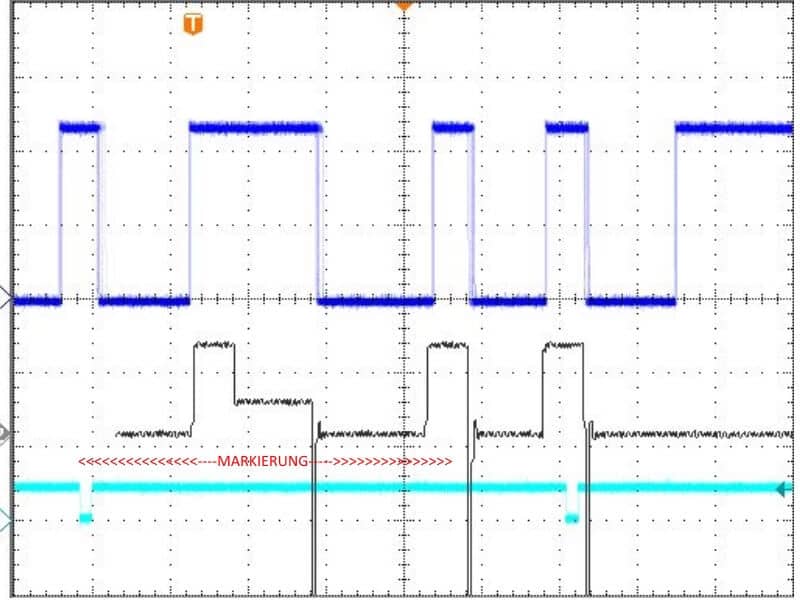

Length units, typing, product properties, and much more can be marked using dot or line codes and can then be analyzed using a camera system or other optical sensors.

Length units, typing, product properties, and much more can be marked using dot or line codes and can then be analyzed using a camera system or other optical sensors.LINE MARKINGS

Web goods (paper, film) or metal surfaces (steel markings) are ideal for color markings. The possible applications vary here, with many different line marking options to reliably ensure assembly points in manufacturing processes or mark quality features in manufacturing and assembly.

Web goods (paper, film) or metal surfaces (steel markings) are ideal for color markings. The possible applications vary here, with many different line marking options to reliably ensure assembly points in manufacturing processes or mark quality features in manufacturing and assembly.DOT MARKINGS

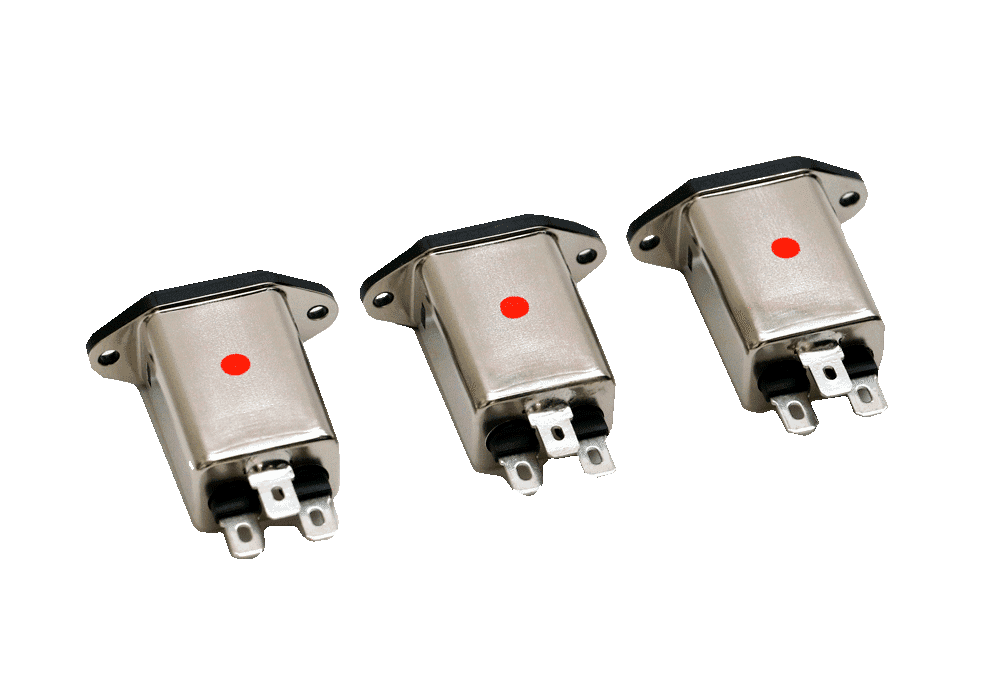

Dot markings with color dots and fluorescent marks as well as simple dot markings can be applied onto work pieces without contact to reliably mark the typing and the product properties.

Dot markings with color dots and fluorescent marks as well as simple dot markings can be applied onto work pieces without contact to reliably mark the typing and the product properties.