COLOR MARKING LINE MARKING

Web goods (paper, film) or metal surfaces (steel markings) are ideal for color markings. The possible applications vary here, with many different line marking options to reliably ensure assembly points in manufacturing processes or mark quality features in manufacturing and assembly.In production, technical challenges have to be met and adapted to new processes on a continuous basis. Modern materials and higher quality standards require more complex specialized manufacturing techniques and project-specific marking systems with color markings. We will support you throughout this process with our marking technology know-how.

- Quality markings

- Typing markings

- And others. Ask us!

- Error markings

- Fitting markings

- Cutting markings

APPLICATION EXAMPLES COLOR MARKINGS – LINE MARKINGS

LINE MARKINGS

COLOR MARKINGS ON FAST PAPER WEBS

A position marking, line marking in redundant design as a web marking/edge marking. Web speed >= 1.200 m/min. Minimum ink agitation thanks to optimized nozzle adjustment. Automatic recognition of the paper web position using a CCD camera or optical sensors from the LMT4 and ML10 series.

Line marking paper web

Overview:

- Marking color black (all primary colors can be supplied)

- No structural effects on the paper web

- Reliable evaluation of the line mark

- Precise calibration

Other benefits at a glance:

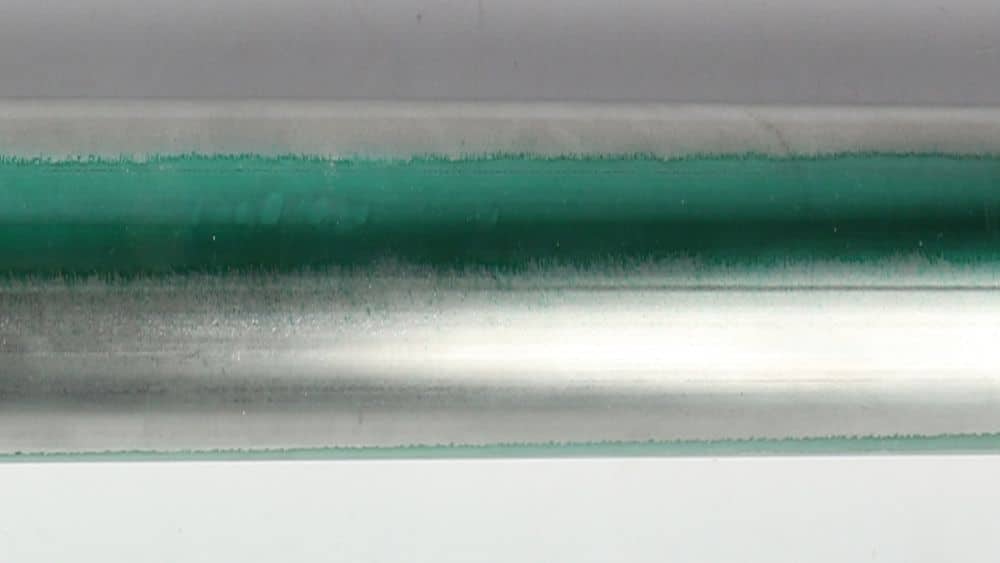

- Accurate, colored line markings, e.g. tubes (steel/plastic), profiles, and extrusion products, and much more.

- Marking of the welding seam during production of metal profiles, sheets, and tubes

- Position markings, bending markings, cutting markings, automatically recognizable

- No damage to the surface thanks to the non-contract application of the media

- Line marks with good adhesion or that can be wiped off easily are possible

- Highly visible color markings, even on oily or wet surfaces

It is the task of MSMS's reliable high-performance marking devices and marking systems to provide permanent, fast, and flexible markings / color markings in manufacturing processes according to the specified parameters. Personalized applications are available for this task for a wide variety of inspection systems and manufacturing processes: to significantly increase quality and productivity.